8H30 – 12H30 / 14h – 17H30 | from Monday to Friday

contact@tacquet-industries.fr

03 21 13 13 00

TRACKER LASER

TRACKER LASER

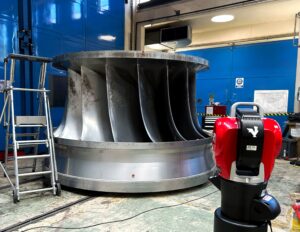

TACQUET INDUSTRIES is able to carry out the dimensional and geometric control of all installations in 3D. Thanks to the experience of our metrologists, we have the ability to assist you on the issues you encounter and our expertise goes beyond simple control.

We are experts in the measurement and analysis of complex assemblies such as power generation machines (hydro-electric, thermal, nuclear) or compressors in petrochemicals.

Integrating measured data into modeling and analysis software allows for optimized project planning and monitoring, making the maintenance process more efficient and collaborative.

We have control tools adapted to the different needs encountered on site: laser trackers (API and FARO), line lasers (Fixtur Laser) and 3D scanner (Creaform).

ASSISTANCE FOR ON-SITE MACHINING

The laser tracker allows a real-time measurement of machining machines, and machined parts, thus ensuring an immediate adjustment and correction of anomalies. With a precision of just a few hundredths of a millimetre, the laser control optimizes the machining process, minimizing human errors and reducing time on site.

Portability and speed of use make it easier to access difficult areas, improving the productivity of field teams.

TACQUET INDUSTRIES is committed to offering tailor-made machining solutions, tailored to the specific needs of each customer. Our expertise allows us to efficiently meet your requirements while guaranteeing superior quality results.