8H30 – 12H30 / 14h – 17H30 | from Monday to Friday

contact@tacquet-industries.fr

03 21 13 13 00

Published on 07/08/2023

Flanges machining Ø8700

Can I machine Ø8700 flanges on site?

Want to know more about the last titanic project recently completed by TACQUET INDUSTRIES teams? Continue reading we will tell you everything.

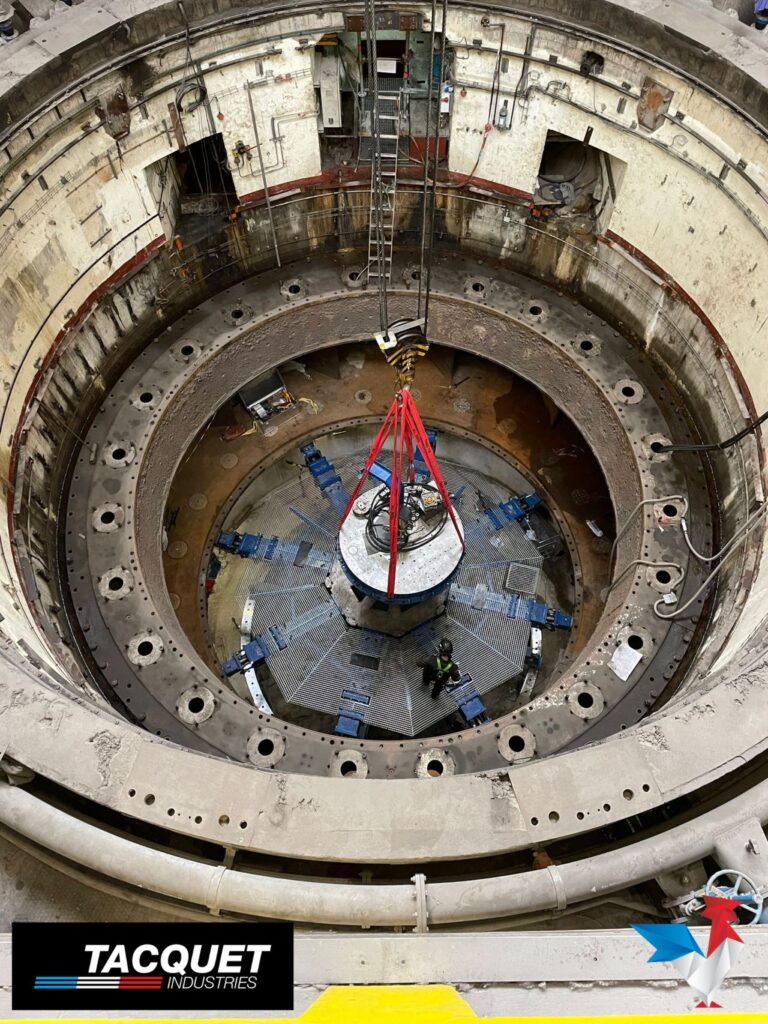

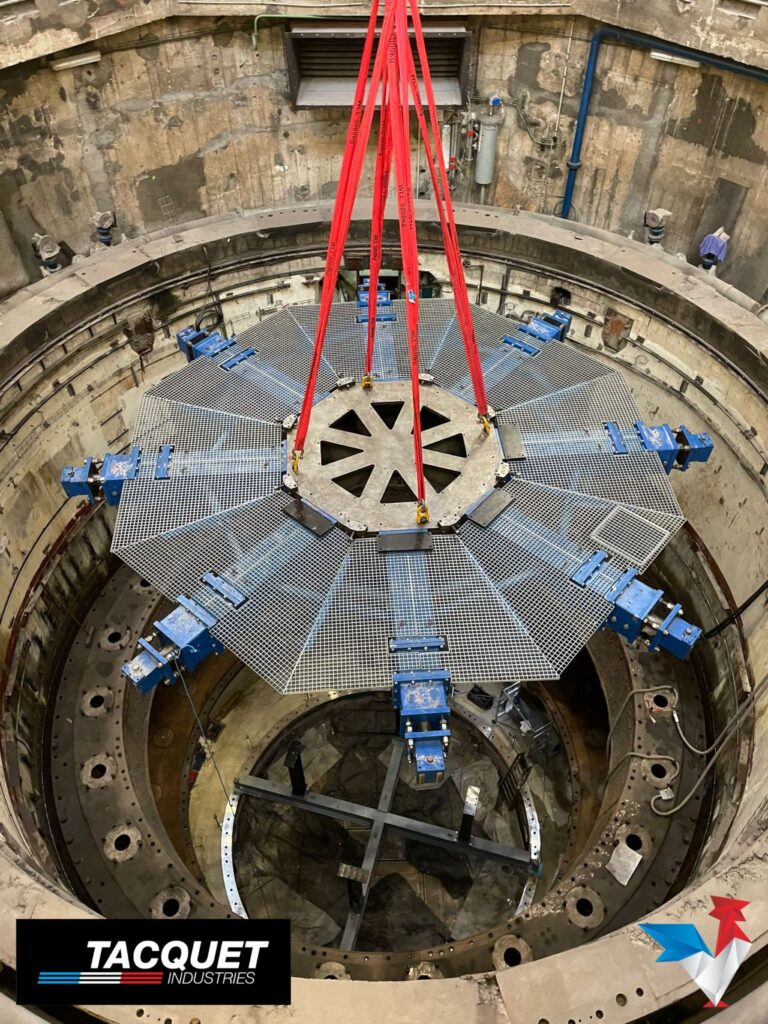

In recent months we had the pleasure of working on the complete renovation of unit 1 of the EDF hydroelectric power station in Ottmarsheim for our customer Voith Hydro. ♻️💧

THE MISSION: 🔍

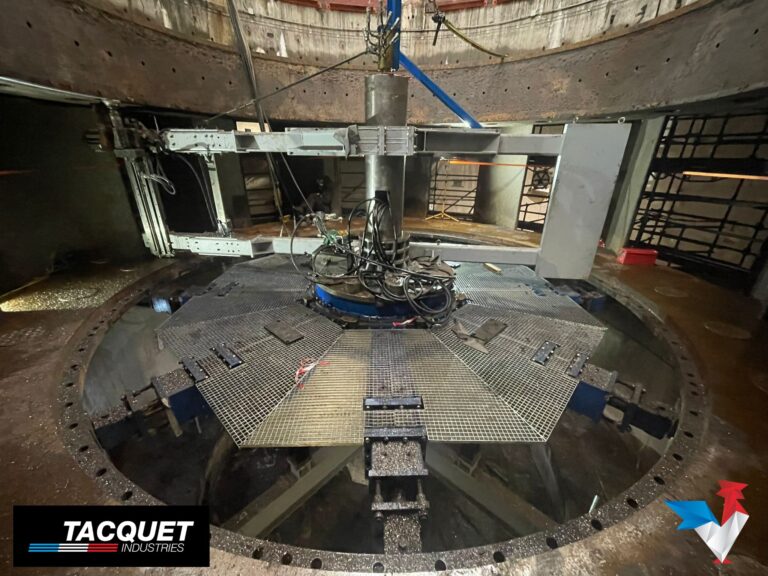

– Machining flange and Ø6050 H7 foundation ring

– Surfacing of the upper face of the inf ring (Ø6900 to Ø8700) then machining of the face and diameter Ø6900

– Surfacing of the inf face of the head cover (Ø6900 to Ø8700)

– Addition of modifications to the 48 Sealing Guide Pots (Drilling/Tapping, Countermeasures)

Tolerances requested: 🔑

– Horizontality and flatness of machined planes: 0.02mm/m

– Surface Condition: Ra 6.3

– Deck depth: 0.1mm

– Bores: H7

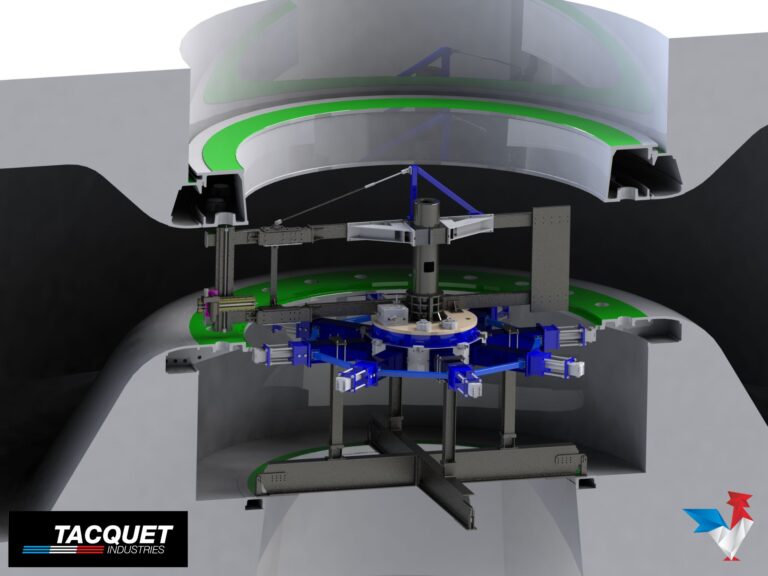

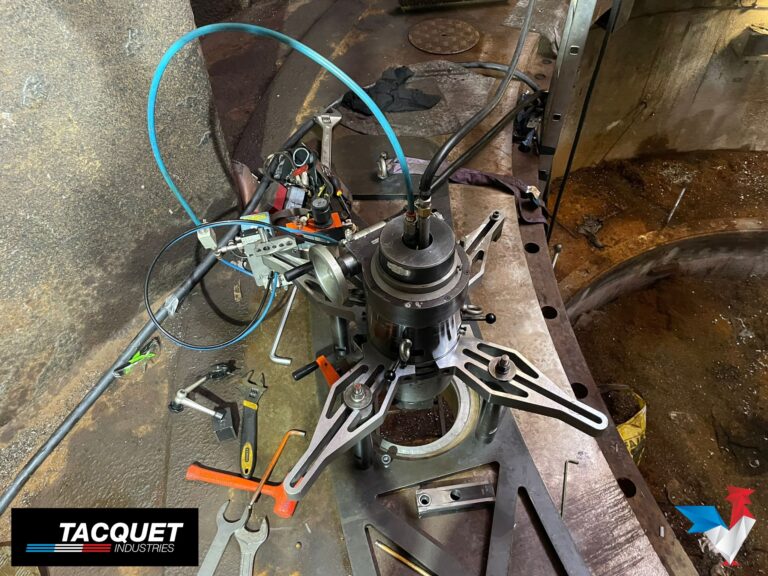

Machines used: TI8500 Boring Machine/ TU400 Boring Machine/ MAB485 Magnetic Drill 🎯

On this site, for its maximum surfacing configuration our machine TI8500 reaches 10m diameter for a mass of almost 20T 🤯

VERDICT: 🏆Successful mission🏆

This new challenge was won thanks to the preparation work carried out by our Design Office as well as the quality of work and the investment of our technicians on site. 💯

We thank Automated Precision Europe GmbH for their involvement in this project.

We also thank our client Voith Hydro for his professionalism and confidence in this project and especially Julien Lacroix, Etienne Pernot and Julia Heinisch for the organization of the site. 🤝