Turbine Francis 𝘎𝘌𝘕𝘐𝘚𝘚𝘐𝘈𝘛

Installing and modifying stainless steel shielding

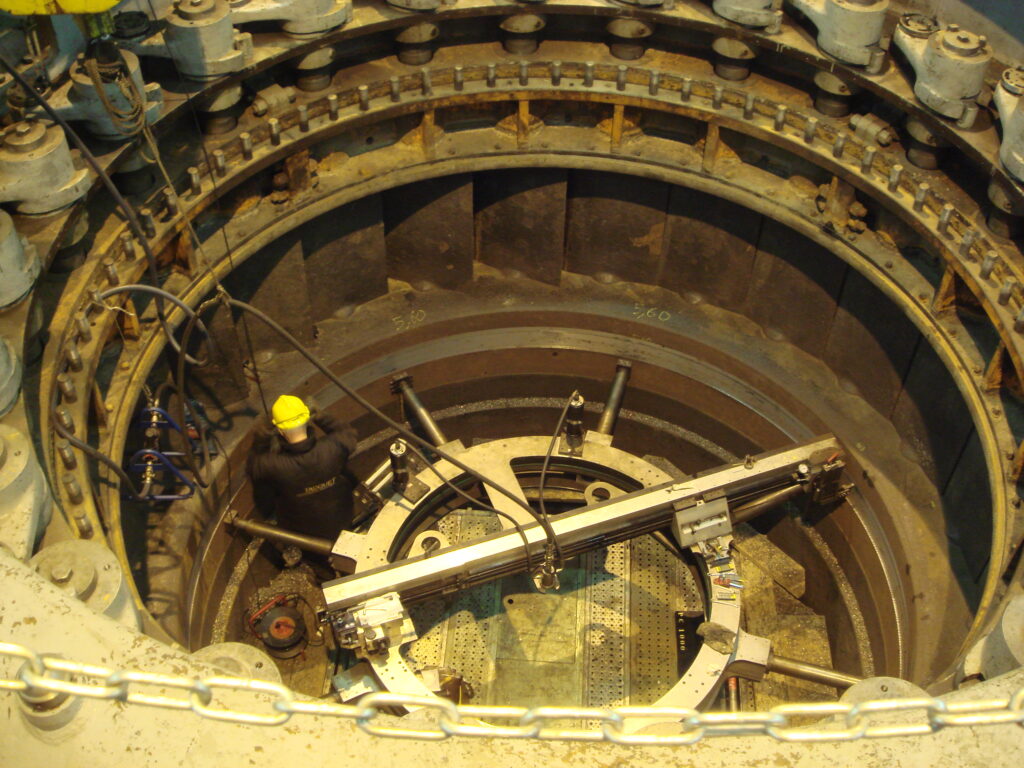

During a turbine maintenance, when the Francis wheel was dismantled by ALSTOM HYDRO, the customer noticed an extremely large cavitation with in some places a total piercing of the shield.

To ensure the optimum restart of the installation within the planned time frame, ALSTOM HYDRO contacted TACQUET INDUSTRIES in order to carry out a feasibility study and complete the work within the given time frame.

Service provided in emergency

Expertise and feasibility study

Definition of means

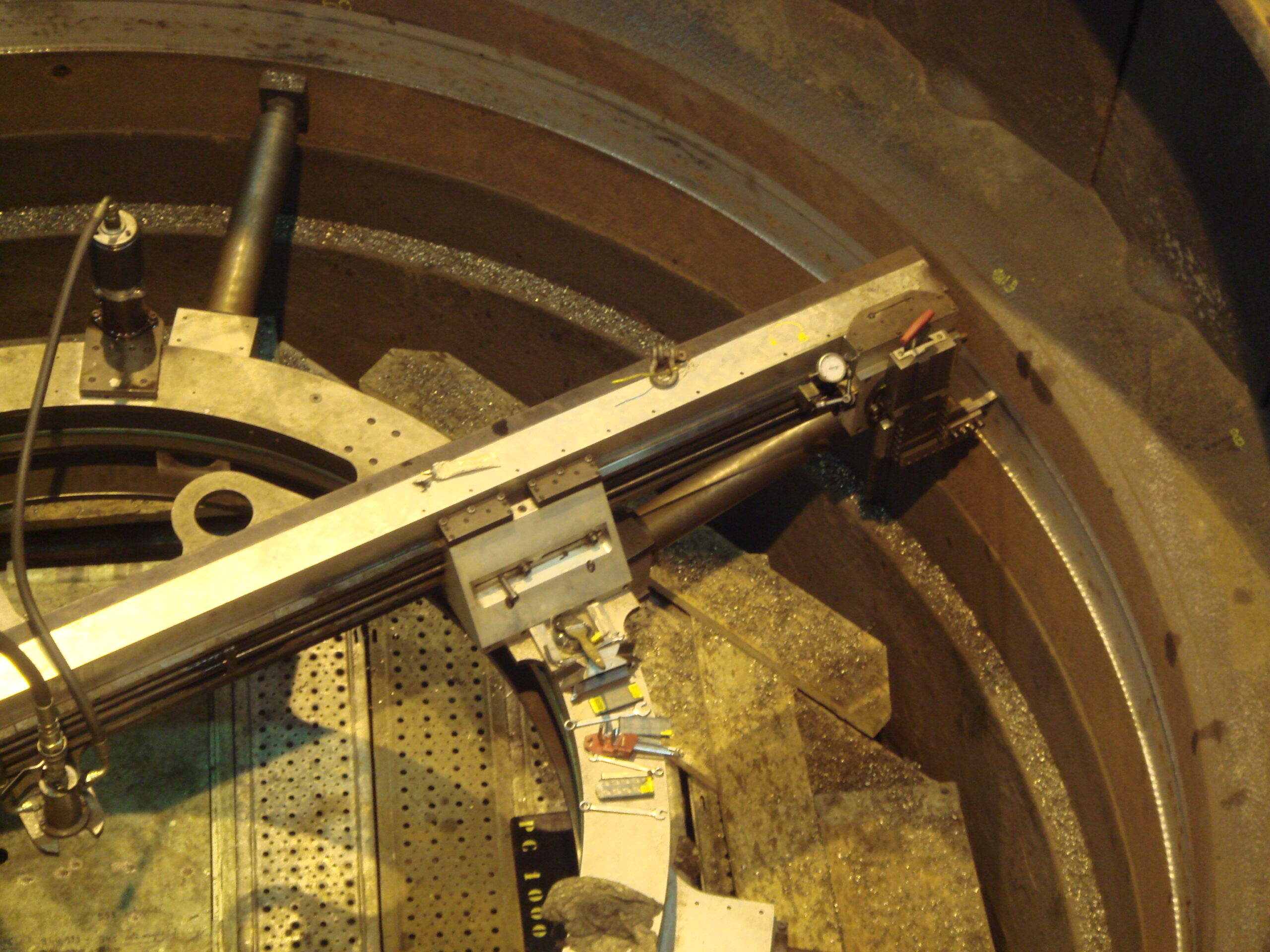

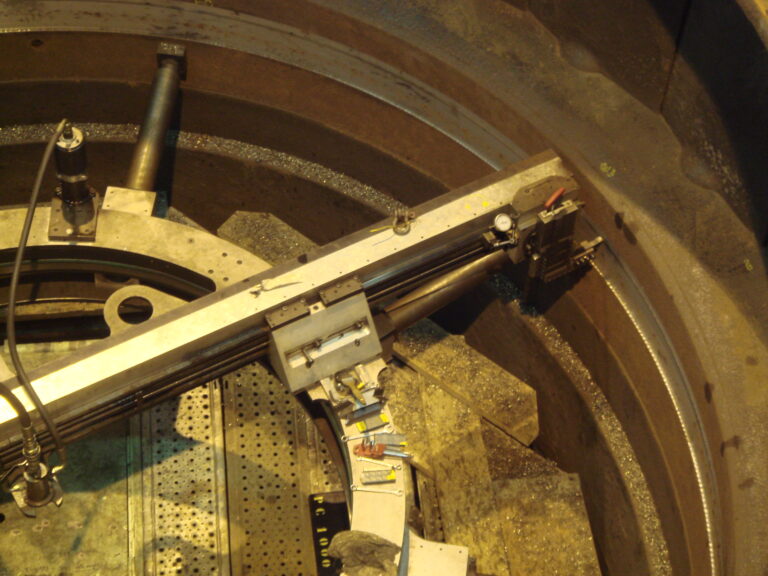

Assembly of a specific machine

Machining of the cavity area

Diameter ø 4m075, Height: 200

Machining thickness 8 mm

Tolerance 0.15 mm

In collaboration with ALSTOM HYDRO, TACQUET INDUSTRIES installed and remanufactured a stainless steel shield with an accuracy of 0.1.