Turbine shaft machining 𝘊𝘈𝘚𝘛𝘌𝘛𝘈𝘙𝘉𝘌

Baigts Castetarbe factory, France

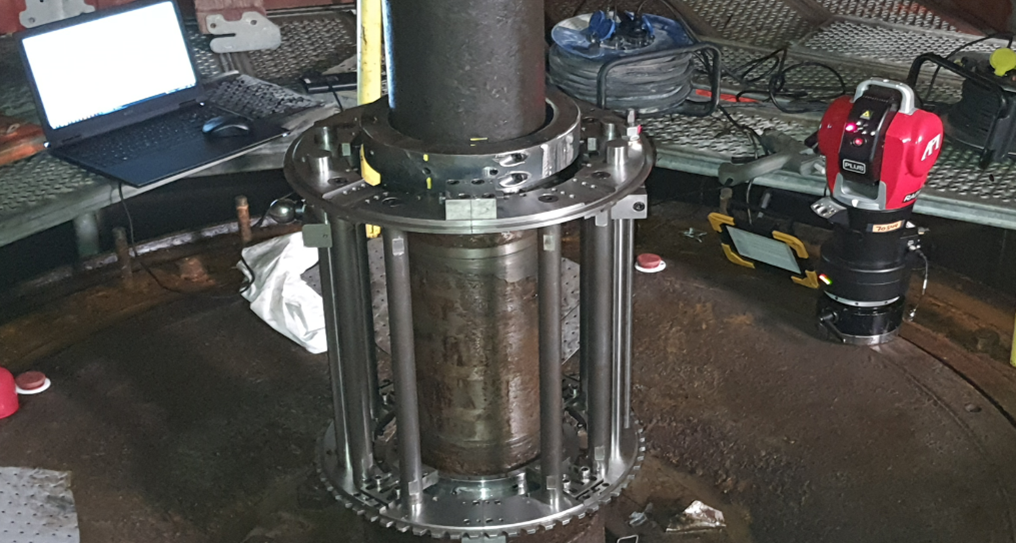

Turbine shaft machining

During 2023, we worked on a turbine shaft at the Baigts Castetarbe Hydroelectric Power Plant in France for our customer EDF.

- GOAL

- TOLERANCES REQUESTED

- ACHIEVEMENT

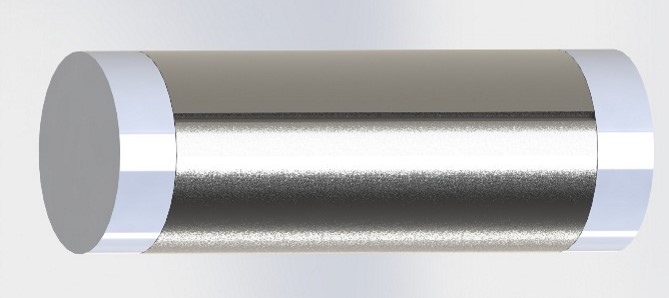

- Machining (delardage) of the shaft of 10mm at minimum radius over a length of 450mm

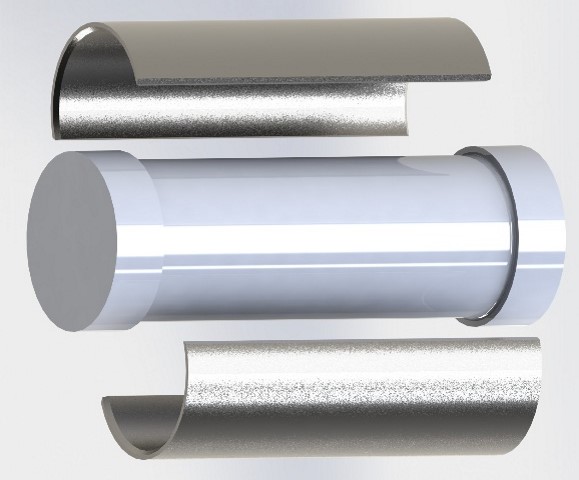

- Welding of 2 half shells (machined in our workshop) on the tree by an external company

- Machining of welded half-shells to obtain the final diameter Ø200

- Diameter tolerance Ø200: 0.1 mm

- Conicity: (0; + 0.1 mm)

- Coaxiality: (0; + 0.2 mm)

- Surface condition: Ra 1.6 (obtained: 0.3/ 0.4)

Our intervention took place in several stages:

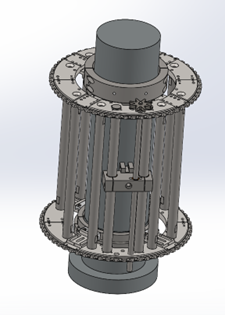

- Step 1: Analysis of the subject in our Design Office (feasibility, 3D modeling of the tree, implementation of our machine in the 3D work environment).

- Step 2: Carrying out pre-work checks (Laser Tracker) by an external company to define the origins and create a reference.

- Step 3: Installation of our machine on site and machining.

- Step 4: Soldering half shells.

- Step 5: Realization of controls (Laser Tracker) by an external company in order to recover the repository and adjust the machine.

- Step 6: Installation of our machine on site and finishing machining.

- Step 7: Completion of after-work checks (Laser Tracker) by an external company.