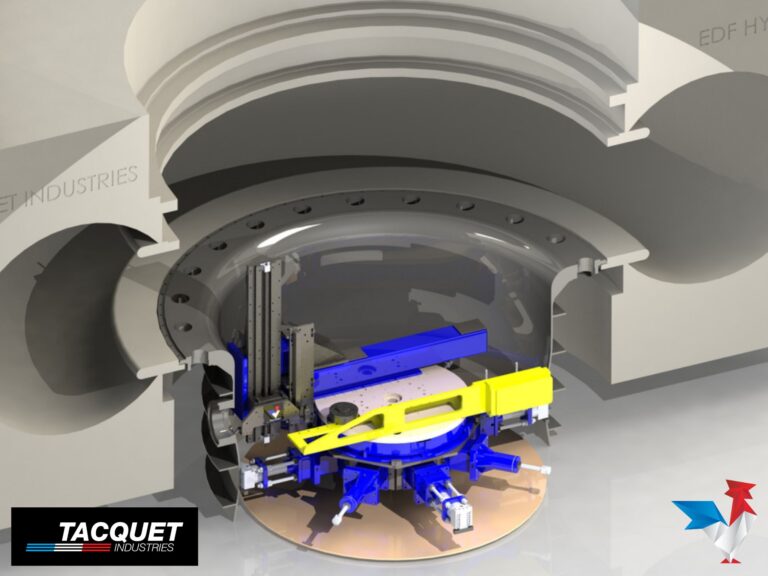

Wheel coat Ø3400

Published on 29/08/2023

Wheel coat Ø3400

Take a wheel coat Ø3400 of a Kaplan turbine by machining and all that on site?! The TACQUET INDUSTRIES teams also know how to do it!

If you want to know more, it’s here 👇

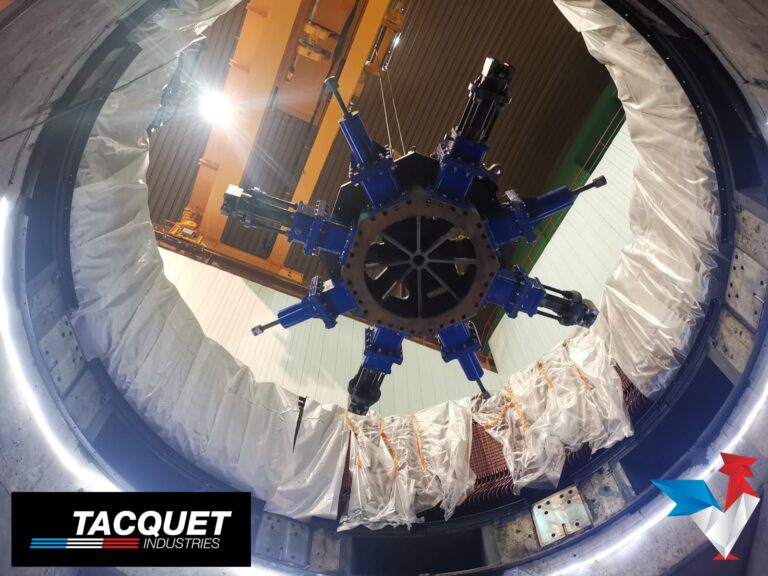

During the month of July, our teams had the privilege of working on the renovation of another hydroelectric power plant group. ♻️💧

THE MISSION: 🔍

– Resumption of the cylindrical and spherical part Ø3400 of the wheel mantle on a height of 1m.

Tolerances requested: 🔑

– Final coast of cylinder diameter and sphere Ø3400

– Surface condition: Ra 3.2 max

Machine used: Boring-Surfacer TI6500 🎯

The subtlety on this site lies in the development of a completely mechanical copier to follow and recreate the original shape of the coat. No CNC was used for this operation. 👌

Intervening on this type of site allows us to improve our techniques in order to deliver an optimal quality of service and services for our customers!

VERDICT: 🏆Successful mission🏆

This new success was achieved thanks to rigorous preparation upstream by our Design Office and the professionalism of our technicians on site. 💯

We thank Automated Precision Europe GmbH for their support on this project.

We also thank our client EDF for its confidence in this project and especially Pol Piedfer and Loic Potel for the organization of the site. 🤝