Turbine shaft repair

Published on 14/12/2023

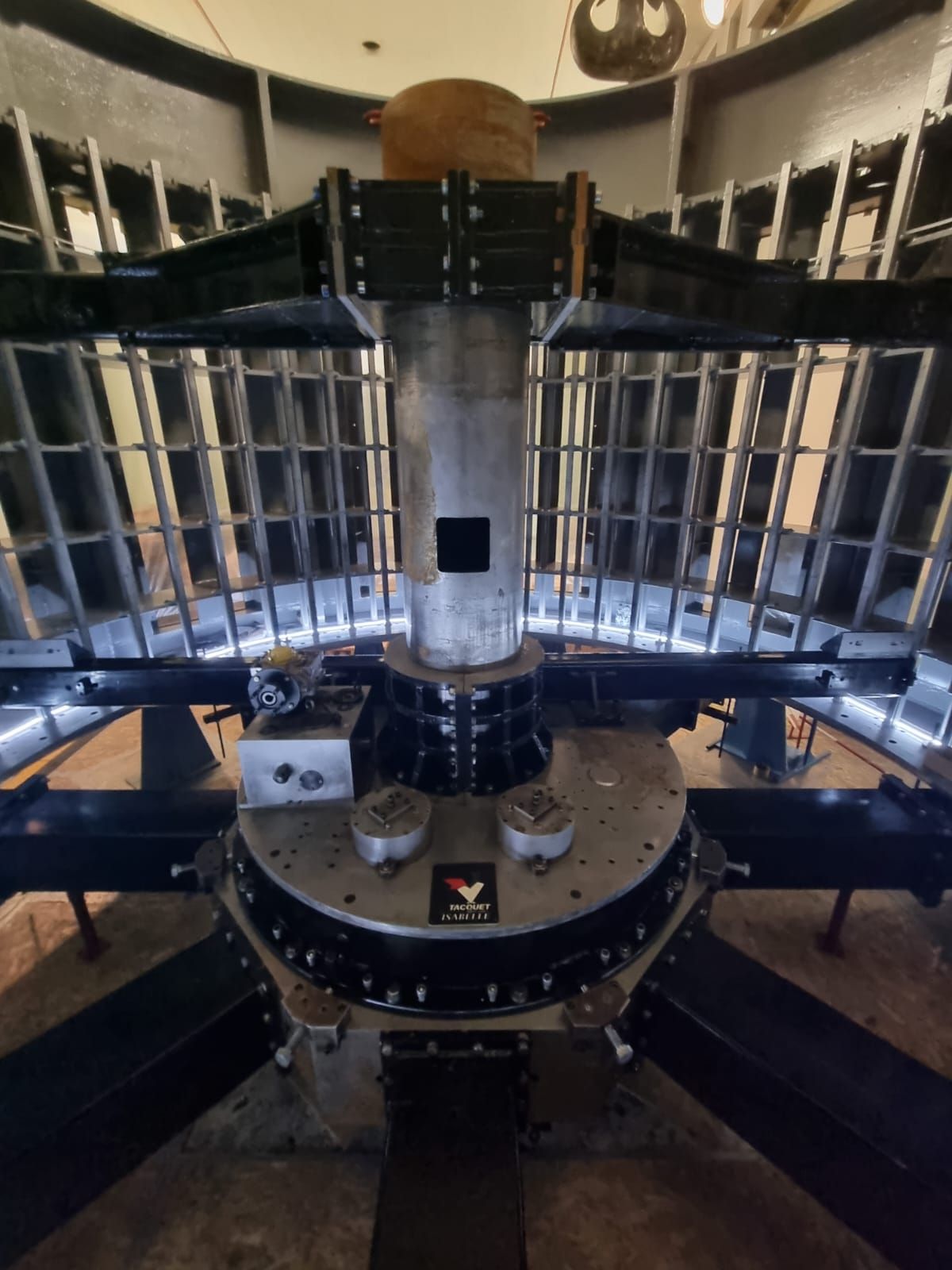

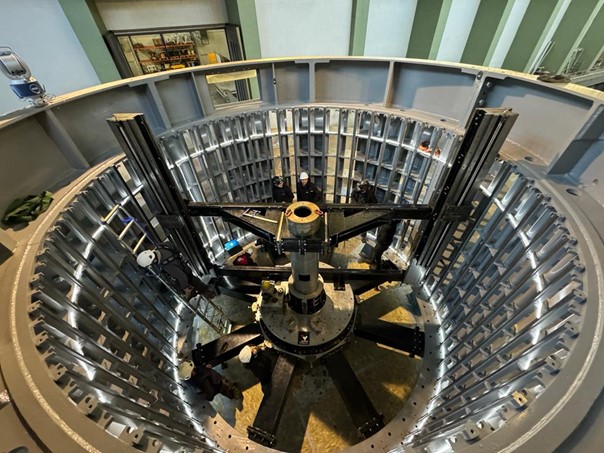

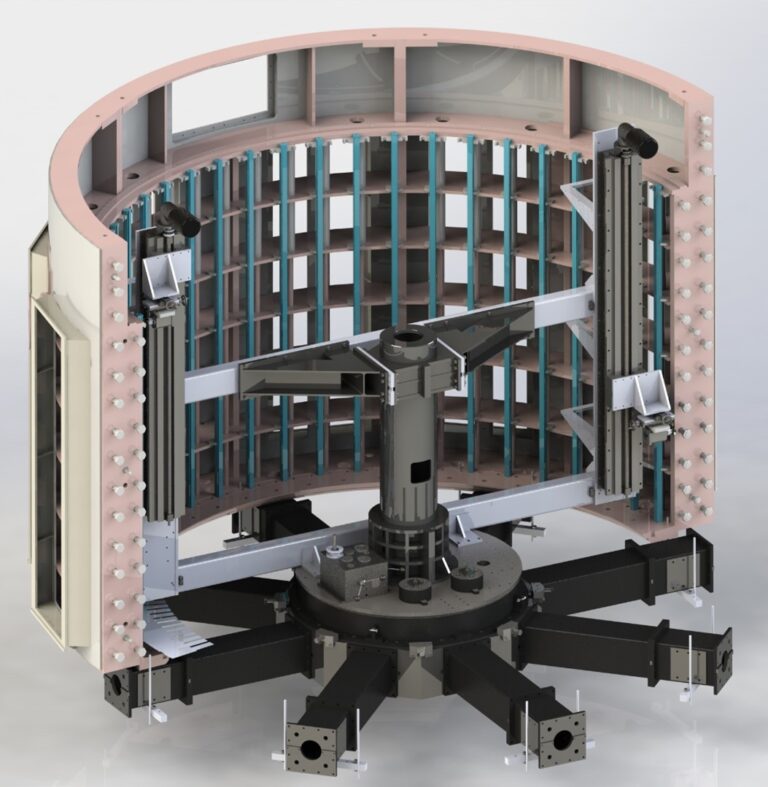

𝐑𝐞𝐩𝐚𝐢𝐫 𝐨𝐟 𝐚 Ø𝟐𝟎𝟎 𝐭𝐮𝐫𝐛𝐢𝐧𝐞 𝐬𝐡𝐚𝐟𝐭 𝐨𝐯𝐞𝐫 𝐚 𝐥𝐞𝐧𝐠𝐭𝐡 𝐨𝐟 𝟒𝟓𝟎𝐦𝐦

𝐷𝑢𝑒 𝑡𝑜 𝑎 𝑝𝑟𝑜𝑛𝑜𝑢𝑛𝑐𝑒𝑑 𝑤𝑒𝑎𝑟 𝑎𝑛𝑑 𝑡𝑒𝑎𝑟 𝑜𝑢𝑟 𝑐𝑢𝑠𝑡𝑜𝑚𝑒𝑟 𝑎𝑠𝑘𝑒𝑑 𝑢𝑠 𝑓𝑜𝑟 𝑎 𝑟𝑒𝑝𝑎𝑖𝑟 𝑠𝑜𝑙𝑢𝑡𝑖𝑜𝑛.

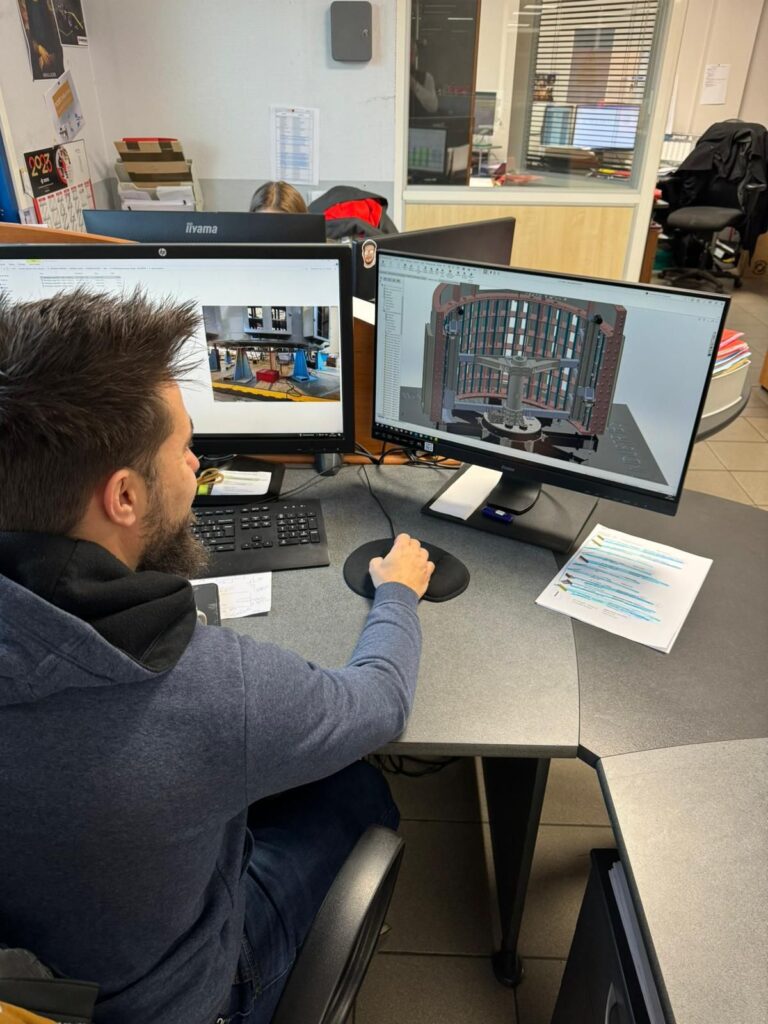

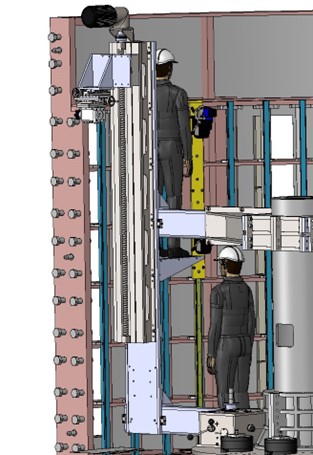

𝑊𝑒 𝑠𝑒𝑎𝑟𝑐ℎ𝑒𝑑 𝑡ℎ𝑒 𝑙𝑎𝑠𝑒𝑟 𝑡𝑟𝑎𝑐𝑘𝑒𝑟 𝐴𝑃𝐼 𝑀𝑒𝑡𝑟𝑜𝑙𝑜𝑔𝑦 𝑓𝑜𝑟 𝑡ℎ𝑒 𝑟𝑖𝑔ℎ𝑡 𝑟𝑒𝑓𝑒𝑟𝑒𝑛𝑐𝑒𝑠.

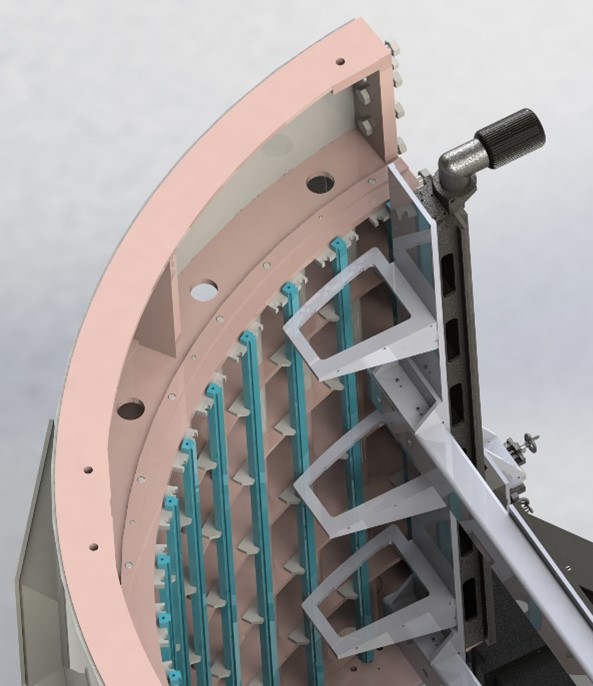

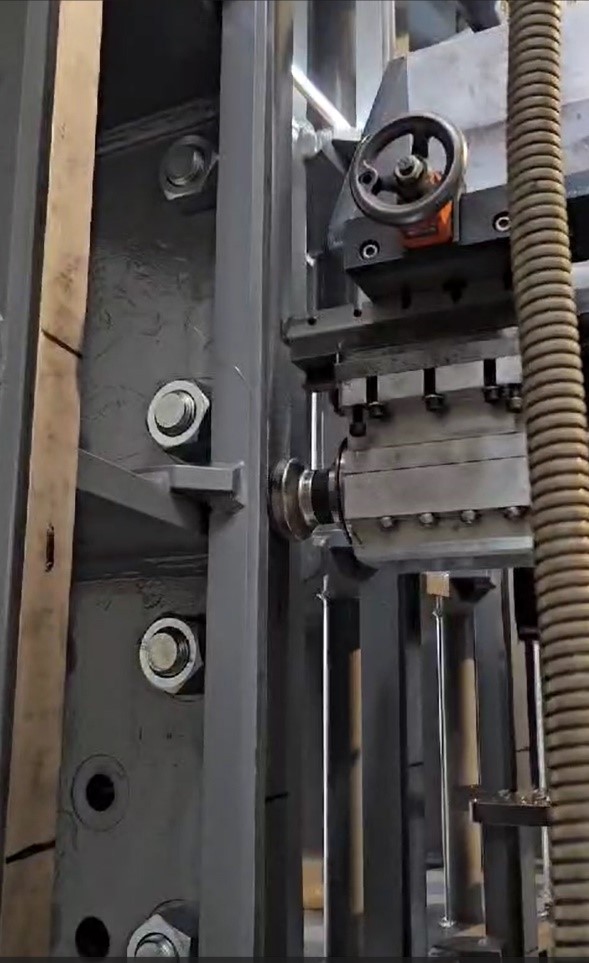

𝑂𝑢𝑟 𝑜𝑟𝑏𝑖𝑡𝑎𝑙 𝑚𝑎𝑐ℎ𝑖𝑛𝑒 𝑎𝑙𝑙𝑜𝑤𝑒𝑑 𝑢𝑠 𝑡𝑜 𝑑𝑒𝑙𝑎𝑟𝑑𝑒𝑟 10𝑚𝑚 𝑡𝑜 𝑡ℎ𝑒 𝑟𝑎𝑑𝑖𝑢𝑠 𝑤𝑖𝑡ℎ 𝑡𝑜𝑙𝑒𝑟𝑎𝑛𝑐𝑒𝑠 𝑖𝑛 𝑡ℎ𝑒 ℎ𝑢𝑛𝑑𝑟𝑒𝑑𝑡ℎ.

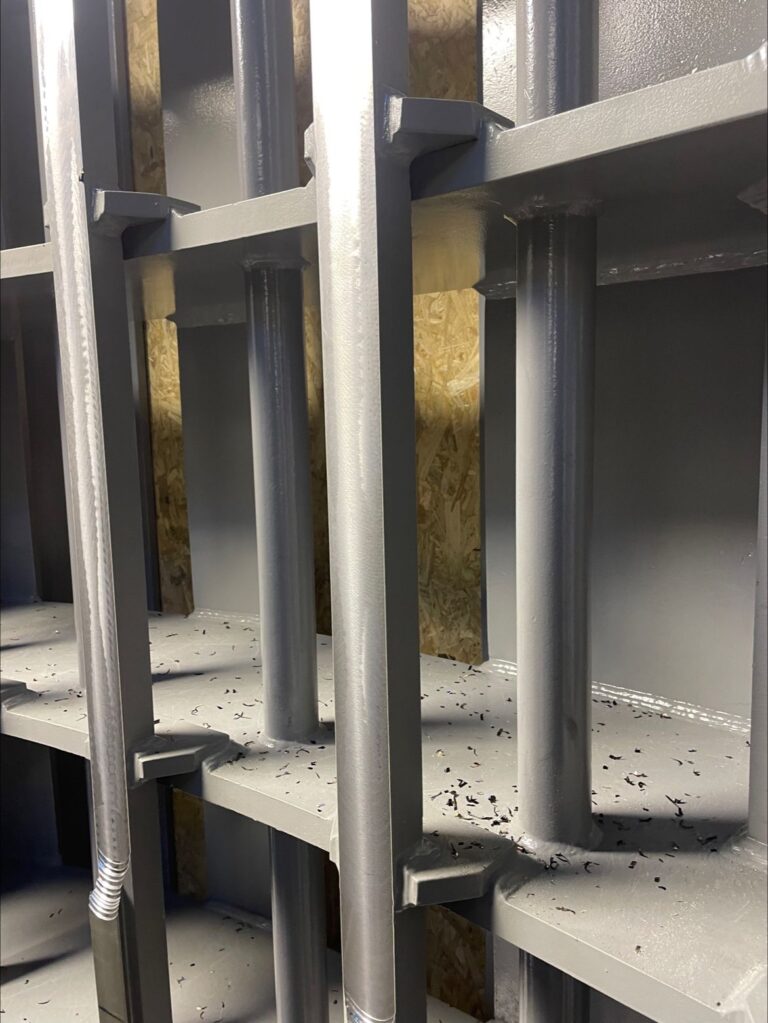

𝐹𝑜𝑙𝑙𝑜𝑤𝑖𝑛𝑔 𝑡ℎ𝑖𝑠 𝑚𝑎𝑐ℎ𝑖𝑛𝑖𝑛𝑔 𝑤𝑒 𝑚𝑎𝑑𝑒 ℎ𝑎𝑙𝑓 𝑠ℎ𝑒𝑙𝑙𝑠 𝑖𝑛 𝑜𝑢𝑟 𝑤𝑜𝑟𝑘𝑠ℎ𝑜𝑝𝑠 𝑎𝑛𝑑 𝑝𝑢𝑡 𝑡ℎ𝑒𝑚 𝑖𝑛 𝑝𝑙𝑎𝑐𝑒 𝑏𝑦 𝑤𝑒𝑙𝑑𝑖𝑛𝑔 𝑤𝑖𝑡ℎ 𝐸𝑑 𝑊𝑒𝑙𝑑𝑖𝑛𝑔 𝑓𝑜𝑟 𝑎 𝑝𝑒𝑟𝑓𝑒𝑐𝑡 𝑡𝑖𝑔ℎ𝑡𝑒𝑛𝑖𝑛𝑔 (𝑤𝑖𝑡ℎ𝑜𝑢𝑡 𝑤𝑒𝑙𝑑𝑖𝑛𝑔 𝑜𝑛 𝑡ℎ𝑒 𝑠ℎ𝑎𝑓𝑡).

𝐴𝑓𝑡𝑒𝑟 𝑤𝑒𝑙𝑑𝑖𝑛𝑔 𝑤𝑒 𝑚𝑎𝑐ℎ𝑖𝑛𝑒𝑑 𝑎𝑛𝑑 𝑔𝑟𝑜𝑢𝑛𝑑 𝑡𝑜 𝑝𝑢𝑡 𝑏𝑎𝑐𝑘 𝑎𝑙𝑙 𝑡ℎ𝑒 𝑑𝑖𝑚𝑒𝑛𝑠𝑖𝑜𝑛𝑠 𝑎𝑡 𝑡ℎ𝑒 𝑜𝑟𝑖𝑔𝑖𝑛 !!

𝐴𝑡 𝑡ℎ𝑒 𝑡𝑖𝑚𝑒 𝑜𝑓 𝑡𝑜𝑑𝑎𝑦 𝑡ℎ𝑒 𝑡𝑢𝑟𝑏𝑖𝑛𝑒 ℎ𝑎𝑠 𝑓𝑜𝑢𝑛𝑑 𝑎 𝑠𝑒𝑐𝑜𝑛𝑑 𝑦𝑜𝑢𝑡ℎ 𝑎𝑛𝑑 𝑖𝑡 𝑡𝑢𝑟𝑛𝑠 𝑝𝑒𝑟𝑓𝑒𝑐𝑡𝑙𝑦.

𝐴 𝑟𝑒𝑎𝑙 𝑝𝑙𝑒𝑎𝑠𝑢𝑟𝑒 𝑡𝑜 𝑤𝑜𝑟𝑘 𝑜𝑛 𝑗𝑒𝑤𝑒𝑙𝑠 𝑜𝑓 𝑡𝑒𝑐ℎ𝑛𝑜𝑙𝑜𝑔𝑦 𝑜𝑓 𝑡ℎ𝑒 𝑡𝑖𝑚𝑒.

𝑇ℎ𝑎𝑛𝑘 𝑦𝑜𝑢 𝑡𝑜 𝑜𝑢𝑟 𝑐𝑙𝑖𝑒𝑛𝑡 𝐸𝐷𝐹 𝑓𝑜𝑟 𝑡𝑟𝑢𝑠𝑡𝑖𝑛𝑔 𝑢𝑠 𝑓𝑜𝑟 𝑡ℎ𝑖𝑠 𝑠𝑒𝑟𝑣𝑖𝑐𝑒.