8H30 – 12H30 / 14h – 17H30 | from Monday to Friday

contact@tacquet-industries.fr

03 21 13 13 00

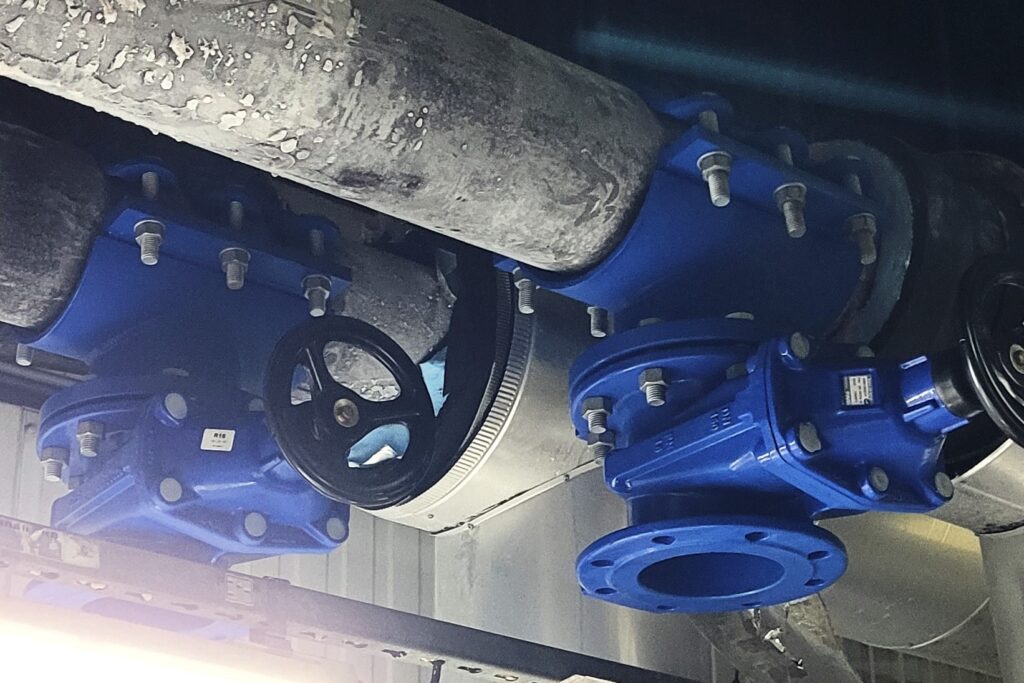

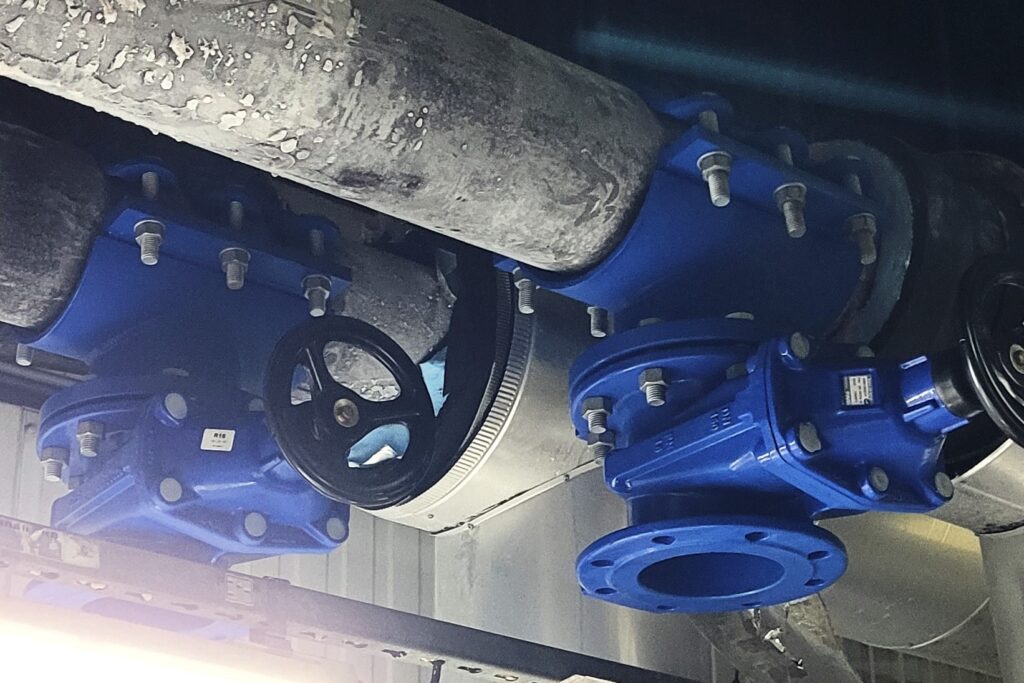

HOT TAPPING

& LINE STOPPING

WHAT IS HOT TAPPING ?

The hot tapping allows openings in in-service pipes to be made, while maintaining their optimal functionality. The expertise in piping allows repairs to be carried out without interrupting the production flow, thus minimizing downtime and economic losses.

When work is required on existing piping, advanced sealing techniques maintain pressure and prevent leaks while facilitating the necessary work. This translates into a significant reduction in downtime and costs associated with the interruption of operations.

ADVANTAGES OF ON-SITE MACHINING

Hot tapping allows for minimal disruption of existing services, ensuring continuity of operations while integrating new equipment or performing maintenance. In addition, this method offers greater flexibility, allowing interventions to be adapted to the specificities of the installations and the needs of the client. By optimizing resource use and reducing downtime, load-loading also contributes to operational cost savings. Finally, it ensures increased safety through rigorous work protocols, limiting the risk of accidents while guaranteeing the quality of interventions.

TACQUET INDUSTRIES is committed to meeting the various demands of customers by offering customized machining services adapted to the specific constraints of each project.

ACHIEVEMENT

For any request for quotation or to discuss your project of machining on site, do not hesitate to contact us. Our team is at your disposal to advise you and offer the most appropriate services to your expectations. We will be happy to support you in the success of your machining projects.

EXAMPLES OF ACHIEVEMENTS

- Rework of shaft line on the machine frames (presses, etc…)

- Bore of tube

- etc…

No posts found!