8H30 – 12H30 / 14h – 17H30 | from Monday to Friday

contact@tacquet-industries.fr

03 21 13 13 00

REAMING

WHAT IS REAMING ?

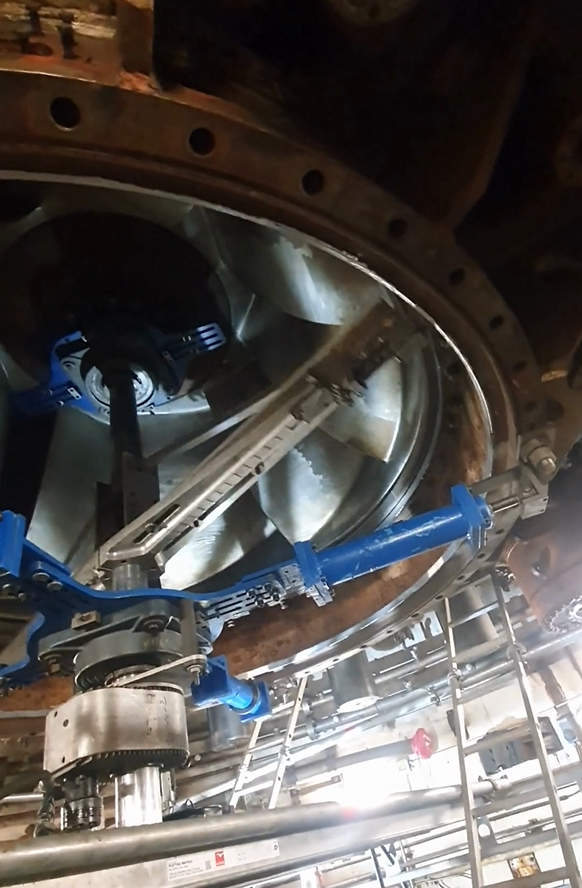

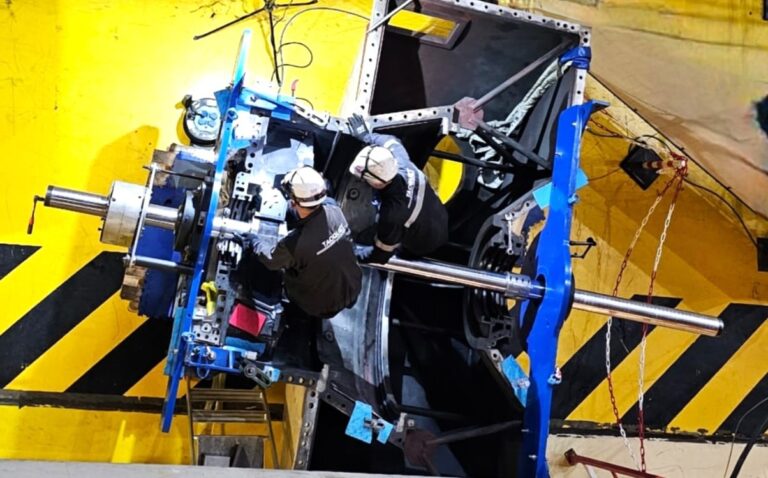

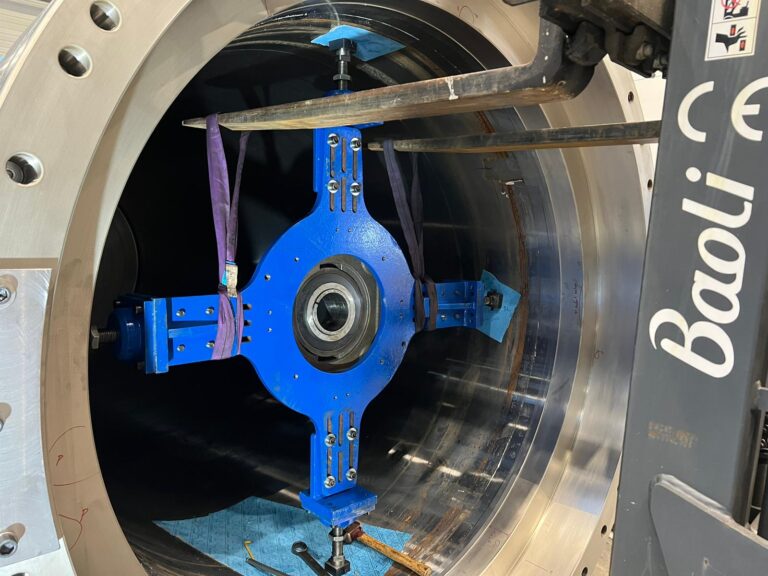

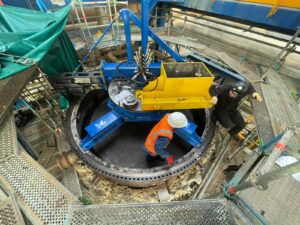

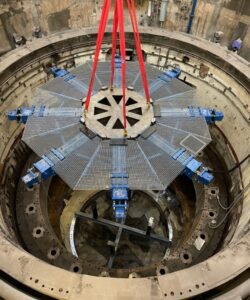

Reaming is an essential technique for enlarging or adjusting existing holes in a part or material without having to disassemble or replace them. The bore allows precise tolerances to be achieved and the operation of mechanical parts is optimized. At TACQUET INDUSTRIES, we put our expertise to your service to perform boring work adapted to your specific requirements. Whether it’s for heavy parts or hard-to-reach components, our skilled technicians have the right equipment to carry out every project.

ADVANTAGES OF ON-SITE MACHINING

By eliminating the need to transport parts to machining centres, companies gain in efficiency and time. This also minimizes the risk of damage during transport. In addition, interventions are done in real time, which reduces downtime and increases productivity.

TACQUET INDUSTRIES meets the specific requirements of each client, adapting to the nature of the projects and their technical constraints. Whether it’s an urgent need or a planned project, we work closely with you to ensure high precision boring. Each intervention is designed to meet the highest standards of quality and reliability, ensuring that your production is kept to a minimum.

ACHIEVEMENTS

For any request for quotation or to discuss your project of machining on site, do not hesitate to contact us. Our team is at your disposal to advise you and offer the most appropriate services to your expectations. We will be happy to support you in the success of your machining projects.

EXAMPLES OF ACHIEVEMENTS

- Rework of shaft line on the machine frames (presses, etc…)

- Bore of tube

- etc…