8H30 – 12H30 / 14h – 17H30 | from Monday to Friday

contact@tacquet-industries.fr

03 21 13 13 00

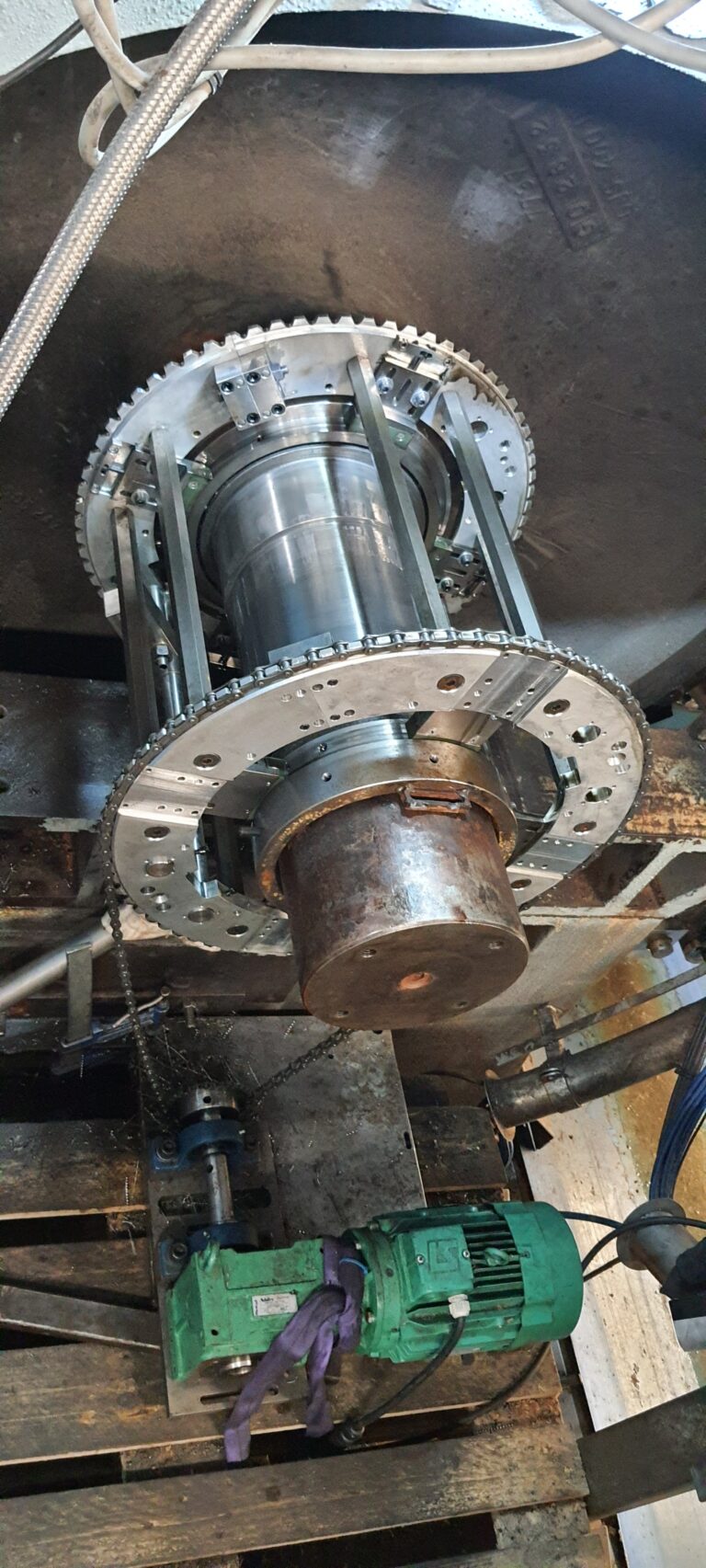

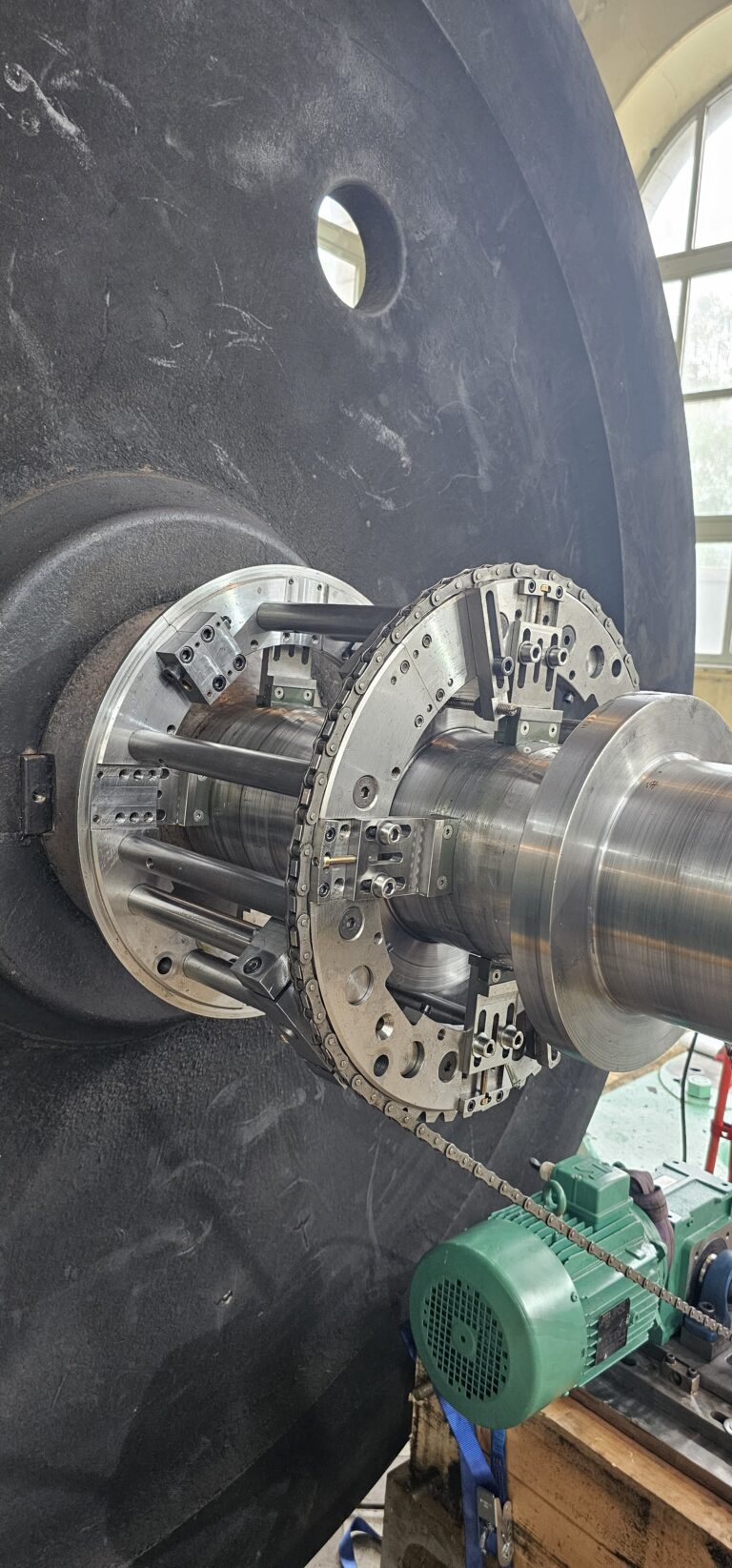

ORBIT MACHINING

WHAT IS ORBITAL RECTIFICATION?

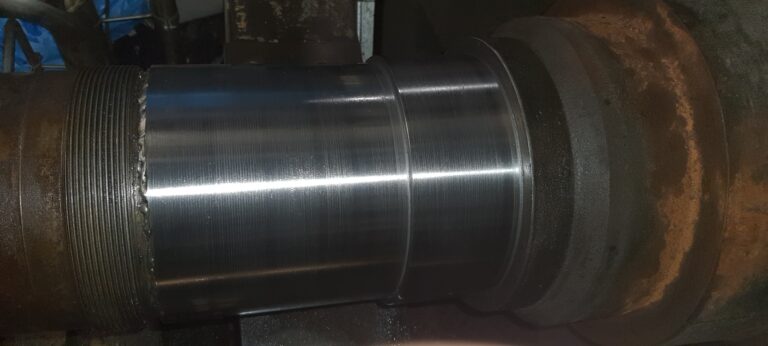

Orbital grinding allows the surface of metal parts to be improved by using a specific milling process. This method involves rotating an abrasive wheel around an axis while moving the workpiece in an orbital manner. This allows very high surface tolerances to be achieved while eliminating defects and ensuring a quality finish.

At TACQUET INDUSTRIES, experts in on-site machining, we implement flexible solutions adapted to the needs of our customers.

ADVANTAGES OF ON-SITE MACHINING

In the field, orbital grinding offers considerable advantages. By intervening directly on the production or maintenance site, our team at TACQUET INDUSTRIES can carry out rectification operations without having to move heavy or bulky elements. This not only reduces downtime, but also the costs associated with transporting parts to the workshop.

ACHIEVEMENT

For any request for quotation or to discuss your project of machining on site, do not hesitate to contact us. Our team is at your disposal to advise you and offer the most appropriate services to your expectations. We will be happy to support you in the success of your machining projects.

EXAMPLES OF ACHIEVEMENTS

- Rework of shaft line on the machine frames (presses, etc…)

- Bore of tube

- etc…