8H30 – 12H30 / 14h – 17H30 | from Monday to Friday

contact@tacquet-industries.fr

03 21 13 13 00

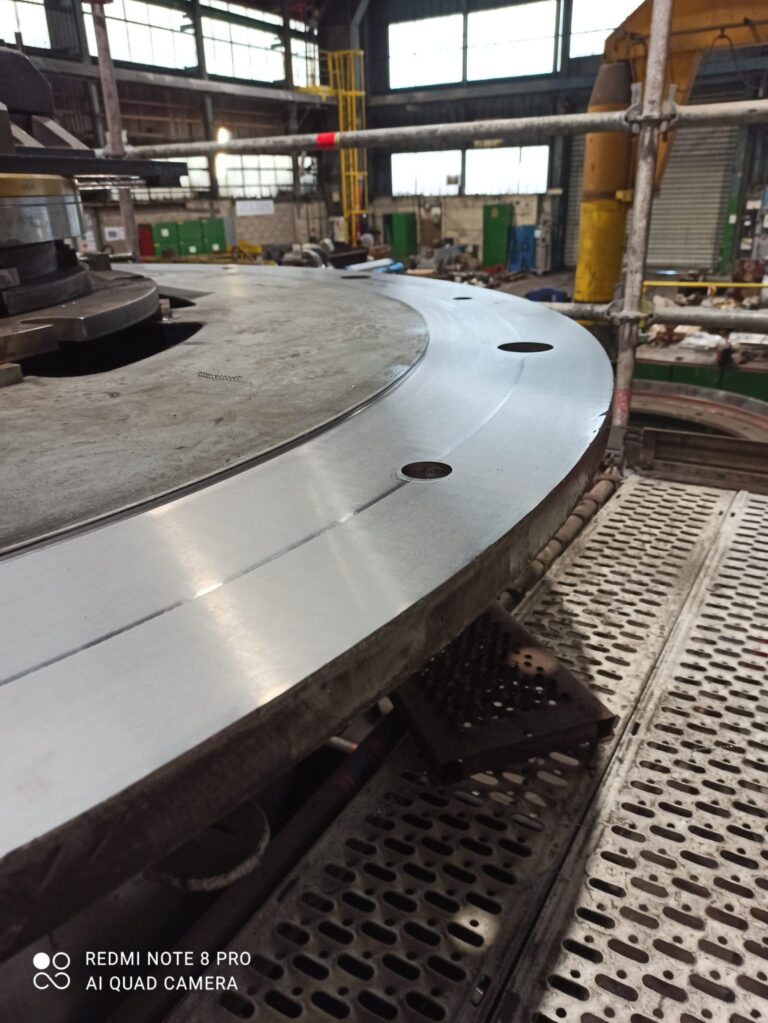

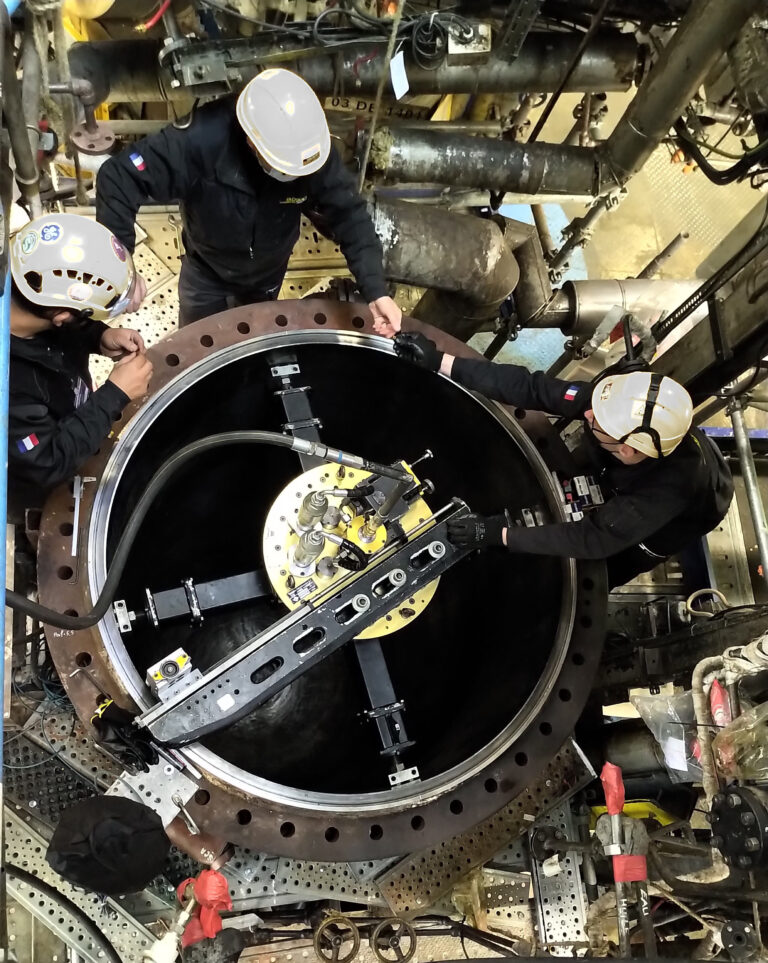

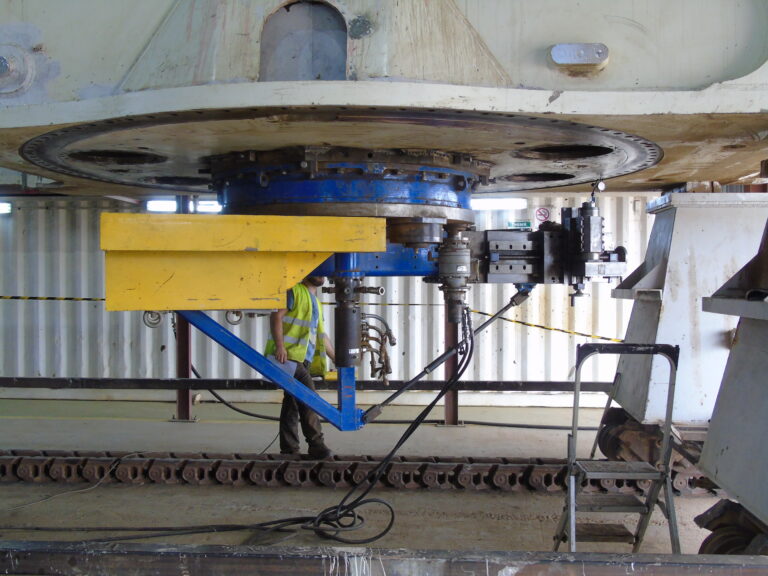

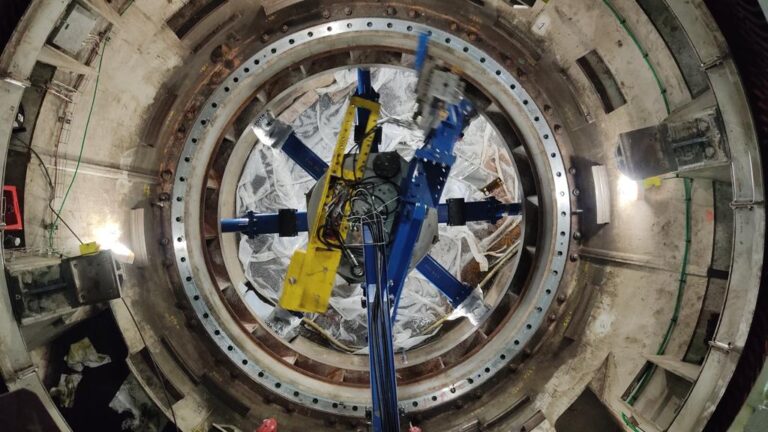

SURFACING

WHAT IS SURFACING ?

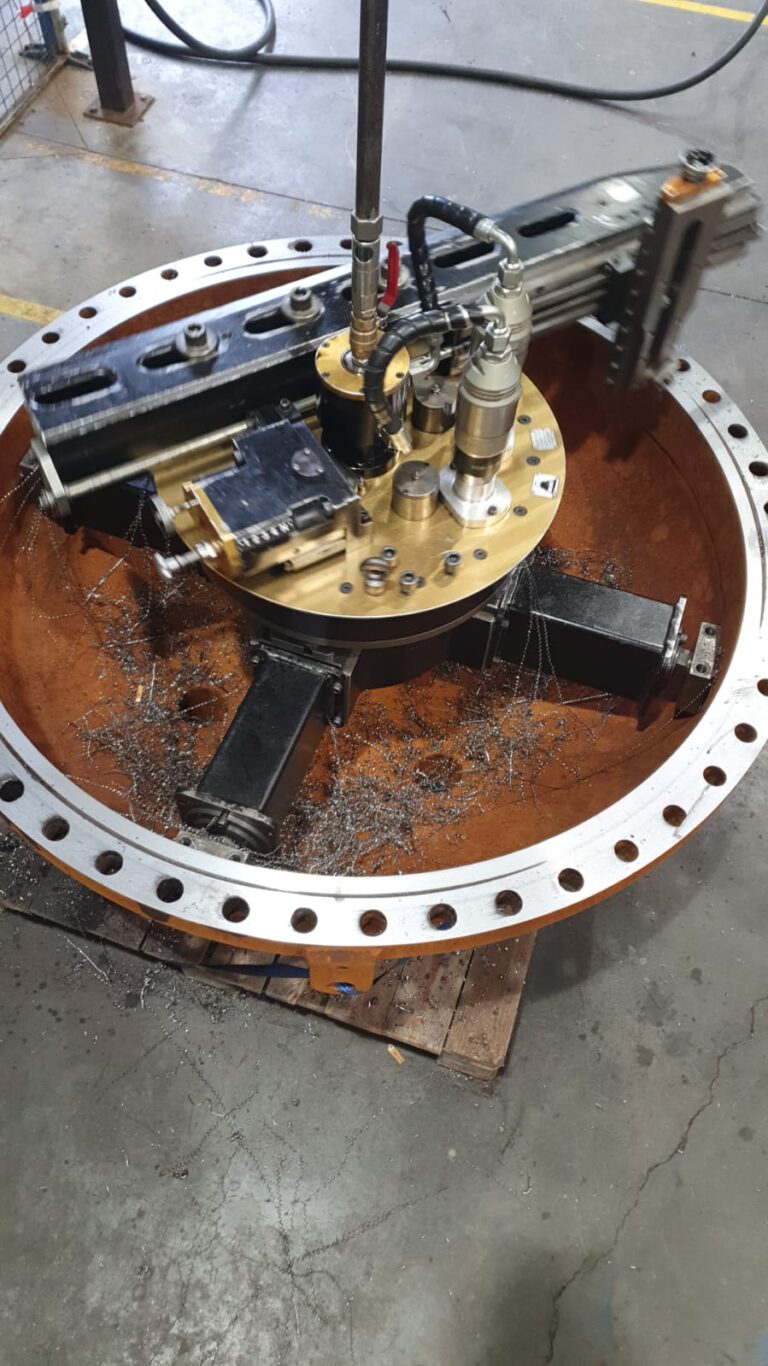

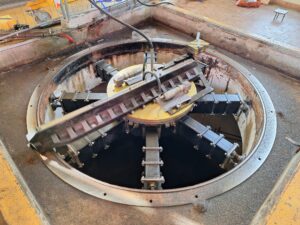

Surface machining is a technique used on site to ensure a precise, flat surface on metal parts or structures. This process is particularly useful for treating damaged or worn surfaces, thus ensuring the proper functioning of equipment while extending its service life. With the expertise of TACQUET INDUSTRIES, this operation is carried out with suitable equipment, guaranteeing optimal results. Whether you need to rectify flanges, joints or supports, our team of professionals is equipped to meet various needs.

AVANTAGES OF ON-SITE MACHINING

On-site machining has many advantages. On the one hand, it significantly reduces production downtime by avoiding the need to transport parts to a manufacturing workshop. On the other hand, it offers greater flexibility as interventions can be carried out according to specific needs in the field. This machining method also helps to optimize costs by limiting logistics costs and avoiding unnecessary dismantling.

AVANTAGES OF ON-SITE MACHINING

On-site machining has many advantages. On the one hand, it significantly reduces production downtime by avoiding the need to transport parts to a manufacturing workshop. On the other hand, it offers greater flexibility as interventions can be carried out according to specific needs in the field. This machining method also helps to optimize costs by limiting logistics costs and avoiding unnecessary dismantling.

ACHIEVEMENT

For any request for quotation or to discuss your project of machining on site, do not hesitate to contact us. Our team is at your disposal to advise you and offer the most appropriate services to your expectations. We will be happy to support you in the success of your machining projects.

EXAMPLES OF ACHIEVEMENTS

- Rework of shaft line on the machine frames (presses, etc…)

- Bore of tube

- etc…